Description

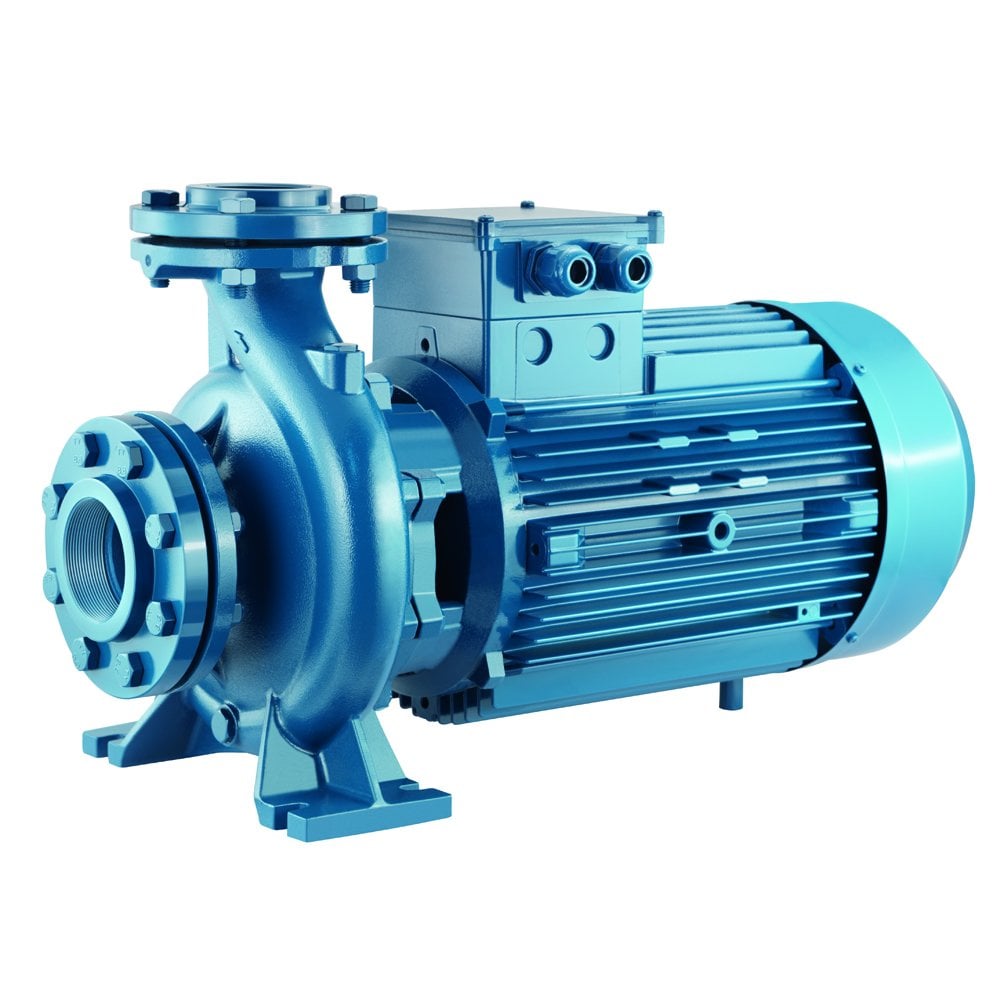

Our Centrifugal Pumps are engineered for smooth, continuous, and energy-efficient flow of liquids in residential, commercial, and industrial operations.

Built with precision-balanced impellers, heavy-duty bearings, and corrosion-resistant materials, these pumps deliver consistent performance even under demanding conditions.

SMP SYSTEMS offers a complete range of single-stage, multistage, end-suction, and vertical inline centrifugal pumps, designed to handle a wide variety of fluids — from clean water to corrosive chemicals.

All models comply with CSA, ISO, and CE standards, ensuring high safety, quality, and performance across Canada and globally.

Types of Pumps Offered:

-

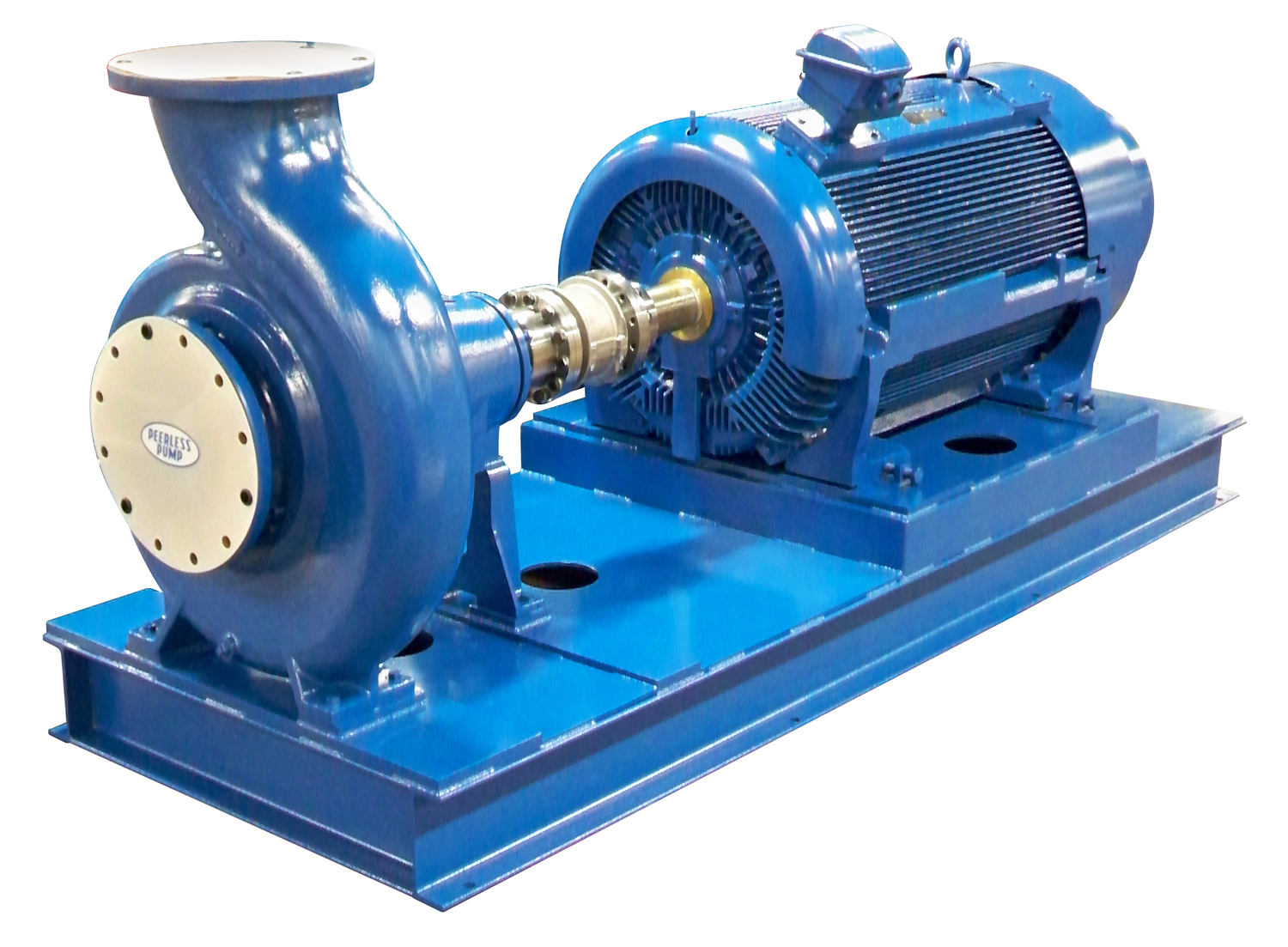

End-Suction Centrifugal Pumps – General-purpose water and fluid transfer

-

Multistage Centrifugal Pumps – For high-pressure and booster applications

-

Vertical Inline Pumps – Compact, space-saving design for process systems

-

Self-Priming Centrifugal Pumps – Ideal for suction lift and dewatering

-

Close-Coupled Pumps – Compact units for commercial installations

-

Split Casing Pumps – For large flow and high-efficiency water handling

-

Chemical-Resistant Centrifugal Pumps – For corrosive or aggressive fluids

Technical Specifications

| Parameter | Specification |

|---|---|

| Pump Type | Single-Stage, Multistage, End-Suction, Vertical Inline |

| Flow Range | 10 – 3000 L/min (customizable) |

| Head Range | Up to 200 meters |

| Pressure Range | Up to 25 bar |

| Power Rating | 0.37 kW – 250 kW |

| Material of Construction | Cast Iron, Stainless Steel (SS304 / SS316), Bronze, Duplex Steel |

| Impeller Type | Enclosed / Semi-Open / Open |

| Seal Type | Mechanical / Gland Packing / Magnetic Drive |

| Operating Temperature | -10°C – 120°C |

| Drive Options | Electric Motor, Diesel Engine, VFD Controlled |

| Protection Class | IP55 / IP68 |

Key Features:

-

High-efficiency flow design with low energy consumption

-

Durable and corrosion-resistant materials

-

Smooth and quiet operation with minimal vibration

-

Easy to install and maintain

-

Available in horizontal and vertical configurations

-

Compatible with water, chemicals, and light slurries

-

Meets Canadian safety and environmental standards

-

Custom-built options for industrial systems

Applications:

-

Water supply and distribution systems

-

Industrial process and cooling operations

-

Irrigation and agricultural systems

-

HVAC and building services

-

Chemical and pharmaceutical industries

-

Food and beverage process lines

-

Firefighting and pressure boosting systems

Certifications & Compliance:

-

CSA Certified – Safety and electrical compliance for Canada

-

ISO 9001 – Quality Management Systems

-

CE Marking – European conformity

-

API / ANSI Standards – Process and industrial compliance

-

RoHS – Environmentally responsible materials

-

Energy Efficiency Compliance – Meets Canadian energy standards

-

Health & Safety (Canada) – Workplace and environmental safety certified

📩 For technical assistance, quotations, or customized pump solutions, contact us at: sales@smpssystems.com

Reviews

There are no reviews yet.