Description

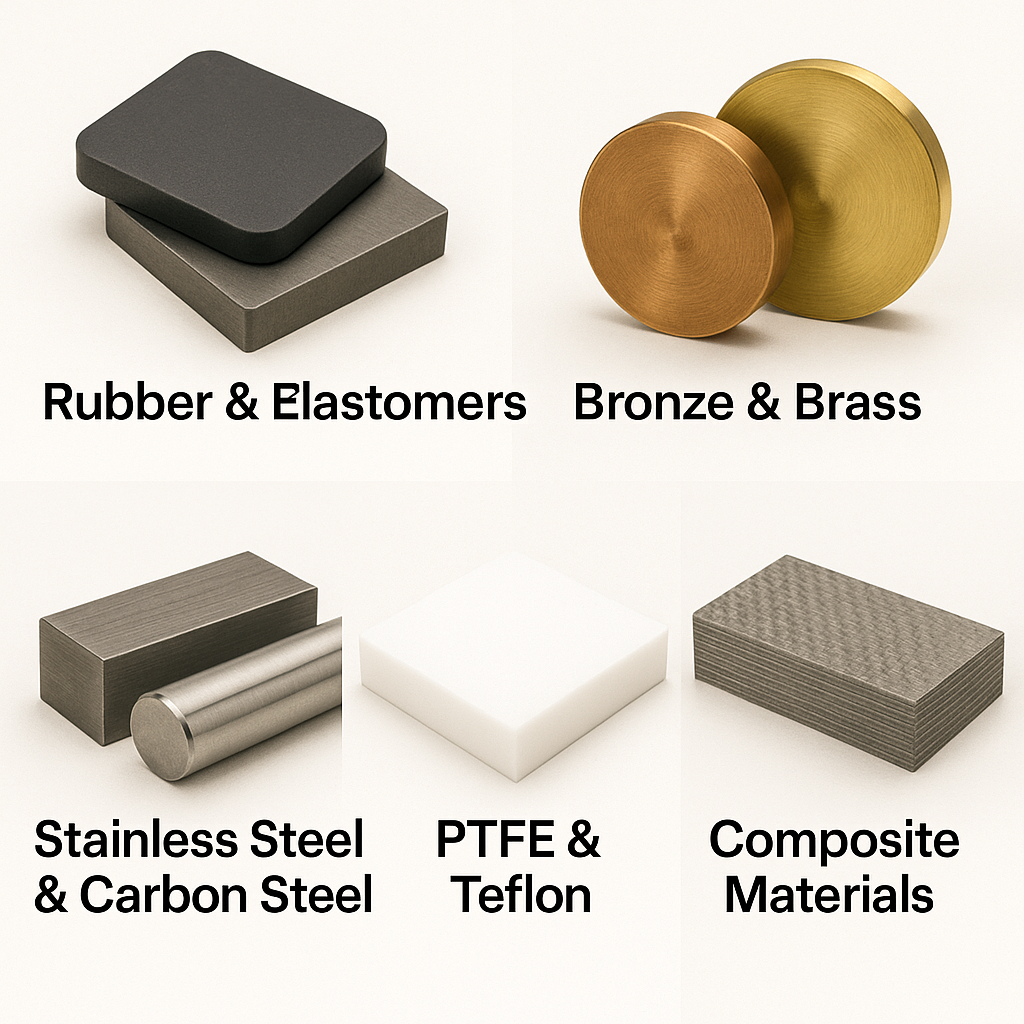

At SMP SYSTEMS, we utilize a wide range of high-performance materials engineered to meet global industrial standards and application-specific requirements. Our material selection ensures superior strength, chemical resistance, and long service life in mechanical, thermal, and corrosive environments.

From metal alloys to advanced polymers and composites, each material is tested and certified to maintain consistency, safety, and reliability in manufacturing, engineering, and process industries.

Material Range

-

Stainless Steel (SS 304, 316, 316L, 410, 420): High corrosion resistance, strength, and hygiene for food, marine, and process applications.

-

Carbon & Alloy Steels: Ideal for high-strength structural, mechanical, and pressure equipment.

-

Brass & Bronze: Excellent machinability and wear resistance for fittings, valves, and electrical components.

-

Polypropylene (PP): Lightweight, chemical-resistant polymer for fluid handling and packaging.

-

PTFE & Teflon: Non-stick, high-temperature-resistant, and chemically inert material for seals and coatings.

-

PVDF Coatings: Superior chemical and UV resistance for protective linings and industrial surfaces.

-

Composite Materials: Reinforced fiberglass, carbon, and aramid fibers offering exceptional strength-to-weight ratio.

-

Rubber & Elastomers: NBR, EPDM, Silicone, and Viton compounds providing sealing and vibration isolation.

-

Hastelloy (C22, C276): Nickel-based superalloy with outstanding resistance to oxidation and strong acids.

Technical Specifications

| Parameter | Specification |

|---|---|

| Temperature Range | -80°C to +500°C (material-dependent) |

| Corrosion Resistance | Excellent (in acids, alkalis, and solvents) |

| Tensile Strength | Up to 1,000 MPa (depending on alloy type) |

| Density Range | 0.9 g/cm³ (PP) – 8.0 g/cm³ (metal alloys) |

| Compliance Standards | ASTM, ISO, ASME, DIN, RoHS, REACH, CE, CSA (Canada) |

Key Features

-

Exceptional mechanical strength and chemical durability

-

Wide temperature and pressure operating range

-

Resistance to wear, corrosion, and oxidation

-

Compatible with food-grade, industrial, and chemical systems

-

Available in rods, sheets, tubes, bars, and custom machined parts

-

Certified materials ensuring traceability and quality control

Applications

-

Process equipment fabrication and piping systems

-

Pumps, valves, seals, and instrumentation

-

Chemical, petrochemical, and marine environments

-

Food and pharmaceutical processing equipment

-

Electrical, mechanical, and structural components

Certifications & Global Compliance

-

ISO 9001 – Quality Management System

-

ASTM / ASME / DIN / ISO – Material and manufacturing standards

-

CE / CSA (Canada) – Safety and performance certification

-

RoHS / REACH – Environmental and chemical compliance

-

FDA / CFIA (Canada) – Food-grade certification (on applicable materials)

📩 For material selection guidance, data sheets, or bulk supply inquiries, contact: sales@smpssystems.com

Reviews

There are no reviews yet.