Description

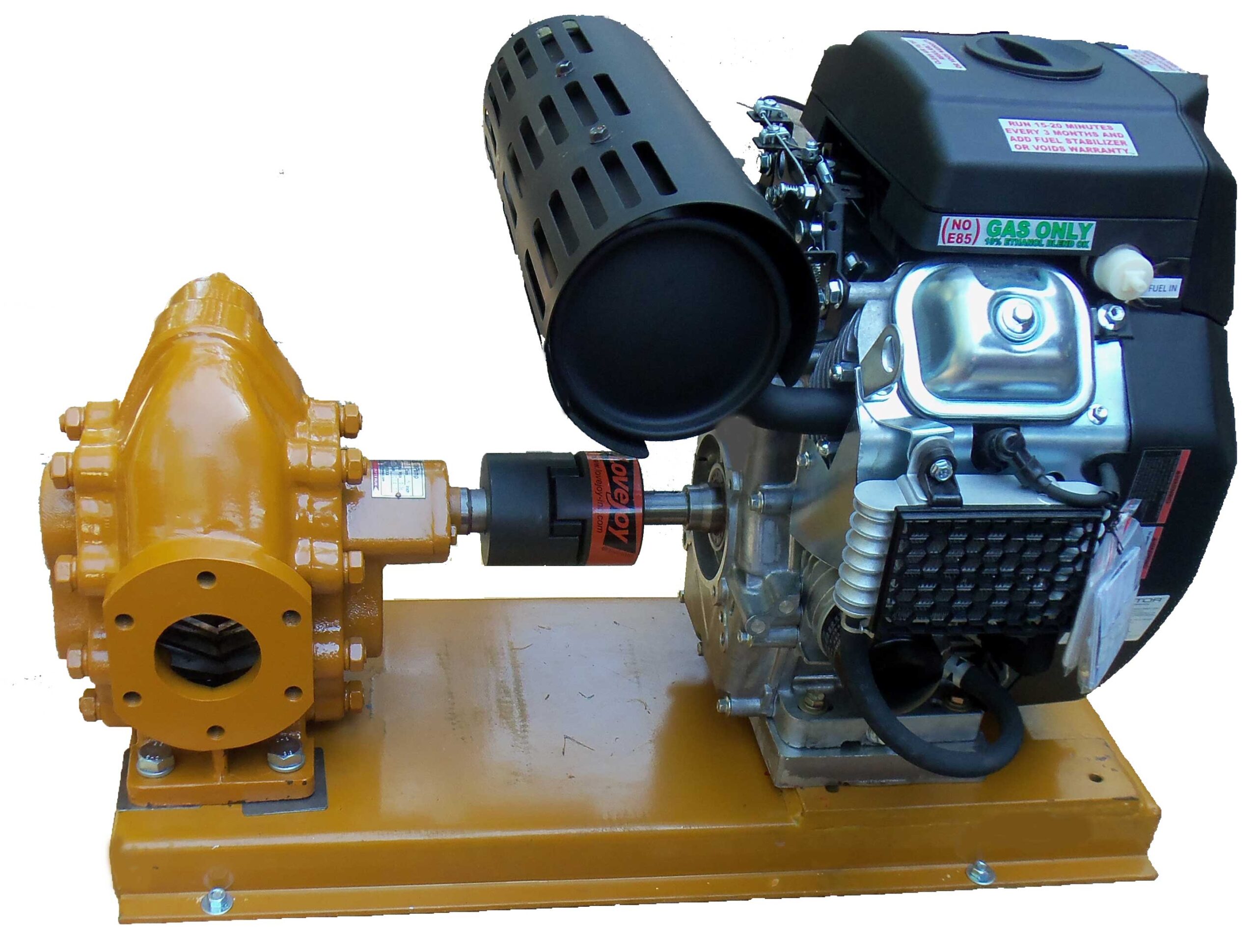

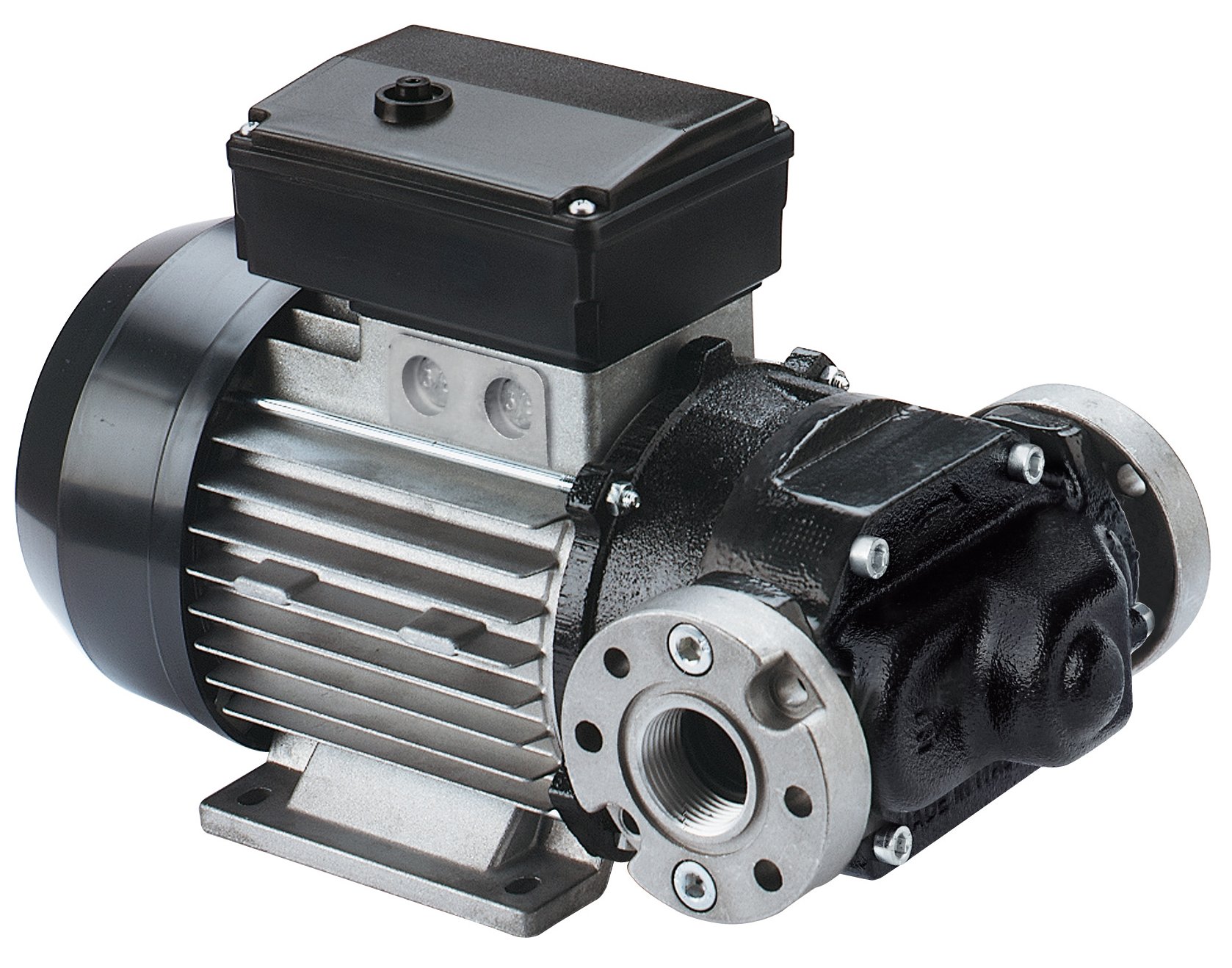

Our Fuel & Oil Transfer Pumps are engineered to handle petroleum-based fluids and lubricants safely and efficiently. Built with high-grade materials, precision sealing systems, and explosion-proof motors, these pumps provide dependable performance in fuel depots, service stations, marine terminals, and industrial plants.

SMP SYSTEMS offers a wide range of pump models — from rotary vane and gear pumps to self-priming and electric transfer units — all designed to meet CSA, ATEX, and CE certifications, ensuring compliance with Canadian safety and environmental standards.

Types of Pumps Offered:

-

Rotary Vane Pumps – For diesel, kerosene, and gasoline transfer

-

Gear Pumps – Ideal for lubricating and heavy oil handling

-

Centrifugal Transfer Pumps – For bulk fuel transfer applications

-

Drum & Barrel Pumps – Portable pumps for drums and containers

-

Diesel Dispensing Units – Complete systems with flow meter and nozzle

-

Explosion-Proof Electric Pumps – For flammable fluid environments

-

Pneumatic & Hand-Operated Pumps – For safe manual operations

Technical Specifications

| Parameter | Specification |

|---|---|

| Pump Type | Rotary Vane, Gear, Centrifugal, Drum, Diesel Dispenser |

| Flow Range | 10 – 1000 L/min (customizable) |

| Pressure Range | Up to 20 bar |

| Viscosity Range | Up to 100,000 cP |

| Temperature Range | -20°C to +80°C |

| Material of Construction | Cast Iron, Stainless Steel (SS316), Aluminum, Bronze |

| Seal Type | Mechanical / Lip / Magnetic Seal |

| Drive Options | Electric Motor (AC/DC), Pneumatic, Hand Operated |

| Power Rating | 0.25 HP – 10 HP |

| Protection Class | IP55 / Explosion-Proof (ATEX / CSA Approved) |

Key Features:

-

Safe transfer of flammable and viscous liquids

-

Explosion-proof and CSA-certified motor options

-

Self-priming and easy to install for quick setup

-

Corrosion-resistant and leak-free design

-

Compatible with multiple fuel types (diesel, petrol, kerosene, oil)

-

Compact, portable, and energy-efficient units available

-

Low noise and vibration operation

-

Long service life with minimal maintenance

Applications:

-

Fuel transfer in service stations and vehicle fleets

-

Oil and lubricant handling in workshops and factories

-

Marine fueling and offshore supply operations

-

Agriculture and heavy machinery refueling

-

Industrial tank filling and draining systems

-

Emergency fuel backup systems

Certifications & Compliance:

-

CSA Certified – Electrical and safety compliance for Canada

-

ATEX Certification – Explosion-proof compliance for flammable environments

-

ISO 9001 – Quality Management Systems

-

CE Marking – European conformity

-

API / ANSI Standards – Industrial performance standards

-

RoHS – Environmentally safe components

-

Energy Efficiency & Safety Standards (Canada) – Meets regulatory norms

📩 For technical specifications, pricing, or customized pump solutions, contact us at: sales@smpssystems.com

Reviews

There are no reviews yet.