Description

Product Description:

Our Custom & Specialty Valves are designed to meet unique operational challenges across various industries — from cryogenic applications and sanitary systems to high-pressure and high-temperature environments. Each valve is custom-engineered for your specific requirements, ensuring durability, performance, and process safety.

Built using premium materials and precision manufacturing standards, these valves deliver tight shut-off, corrosion resistance, and smooth operation even under the toughest conditions.

We offer a complete range of specialized valve designs, including:

-

Cryogenic Valves – For LNG, liquid nitrogen, and low-temperature gas handling

-

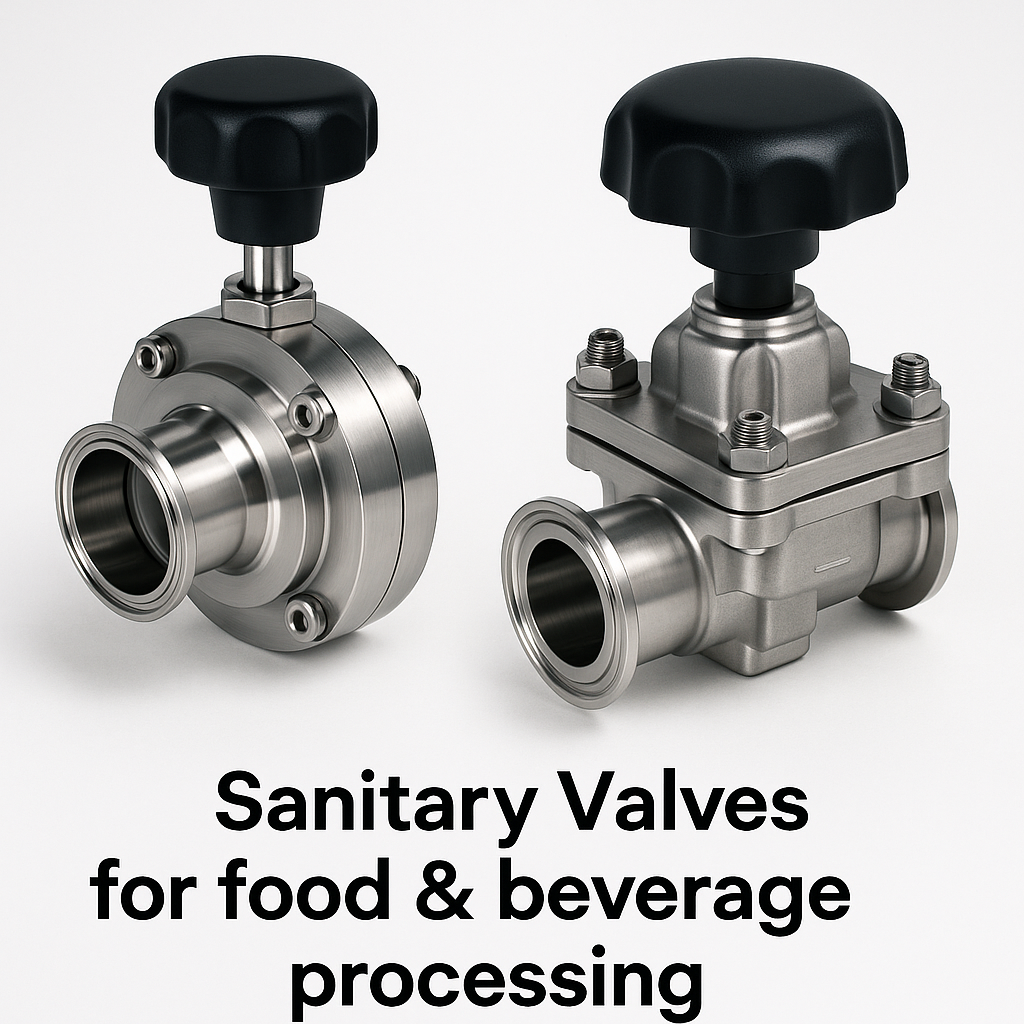

Sanitary Valves – For hygienic use in food, beverage, and pharmaceutical processing

-

High-Pressure & High-Temperature Valves – Built for extreme process environments

-

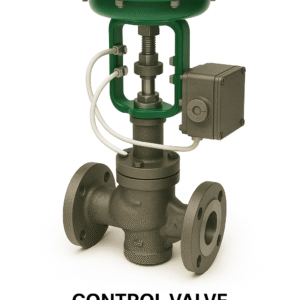

Control & Regulating Valves – For precise flow and pressure control

-

Double Block & Bleed Valves – For maximum isolation and safety

-

Jacketed Valves – For viscous or temperature-sensitive media

-

Vacuum Valves – For controlled vacuum and cleanroom applications

-

Custom Alloy or Coated Valves – Tailored for corrosion or abrasion resistance

Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Types | Cryogenic, Sanitary, High-Pressure & High-Temperature, Control, Double Block & Bleed, Jacketed, Vacuum, Custom Designs |

| Sizes Available | ½” to 48” (custom sizes available) |

| Body Materials | Carbon Steel, Stainless Steel, Duplex Steel, Bronze, Inconel, Hastelloy, Alloy Steel |

| Pressure Ratings | ANSI Class 150 – 2500 / PN10 – PN420 |

| Temperature Range | -196°C to +600°C (depending on material and design) |

| End Connections | Flanged, Threaded, Welded, Tri-Clamp, Quick-Connect |

| Operation | Manual, Gear, Pneumatic, Hydraulic, Electric |

| Testing Standards | API 598 / ASME B16.34 / ISO 5208 / 3A (for sanitary valves) |

Key Features:

-

Custom-built valves for specialized process applications

-

Cryogenic and high-temperature resistance

-

Hygienic design for sanitary and food-grade environments

-

Corrosion-resistant materials and coatings for chemical compatibility

-

Automation-ready with pneumatic or electric actuators

-

Leak-tight, maintenance-friendly, and durable performance

-

Compliant with international safety and quality standards

Applications:

-

Oil & Gas, Petrochemical, and Refinery Operations

-

Food, Beverage, and Pharmaceutical Manufacturing

-

Cryogenic & LNG Facilities

-

Chemical Processing and Power Generation Plants

-

Water Treatment, Desalination, and Marine Systems

-

Research Laboratories and Vacuum Systems

Certifications:

-

API / ASME / ISO – Global valve design and performance standards

-

CE Marking – European conformity

-

ISO 9001 – Quality Management System

-

3A / FDA – Food-grade and sanitary compliance

-

RoHS – Environmental compliance

-

CSA (Canadian Standards Association) – Certified for use in Canada

📩 For custom design or product inquiries, contact us at: sales@smpssystems.com

Reviews

There are no reviews yet.