Description

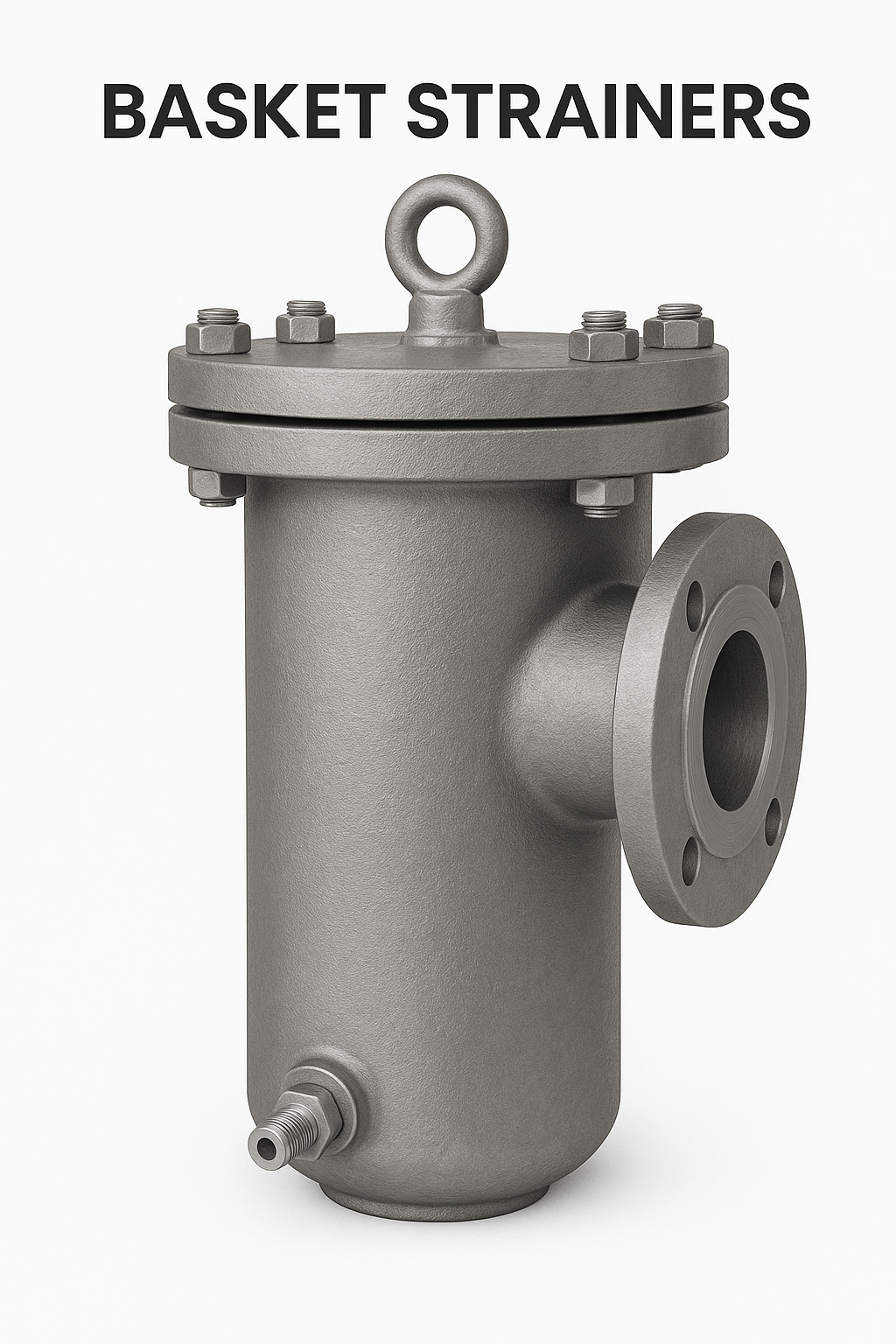

Our Basket Strainers are heavy-duty pipeline filters designed to remove large particles, debris, and solids from liquid flow systems. Built with a basket-type screen housed in a robust body, these strainers protect pumps, valves, meters, and process equipment from damage and clogging. The top-removable basket allows easy cleaning and replacement without removing the strainer body from the pipeline.

Available in simplex (single basket) and duplex (twin basket with change-over valve) versions, these strainers are suitable for continuous or batch-type operation. They can handle high flow rates and dirt loads, making them ideal for water, oil, chemical, and viscous fluid filtration in industrial, marine, and utility applications.

Certified to ISO 9001 and CE standards, our basket strainers offer reliable and efficient protection with minimal maintenance needs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Strainer Type | Basket (Simplex / Duplex) |

| Mesh/Micron Rating | 10 – 200 |

| Sizes Available | ½” – 3″ (larger on request) |

| Connection Ends | Flanged, Threaded (NPT/BSP), Butt Weld, Socket Weld |

| Operating Pressure | Up to 25 bar (higher pressure models on request) |

| Temperature Range | -20 °C – 250 °C |

| Screen Material | SS304, SS316, Monel, Hastelloy |

| Body Materials | Cast Iron, Ductile Iron, Carbon Steel, SS304, SS316 |

| Cover Type | Bolted, Quick-Release, Hinged |

| Installation Orientation | Horizontal (standard), vertical on request |

Features & Benefits

-

High-capacity basket screen for large dirt holding

-

Easy top cover removal for quick basket cleaning

-

Duplex models allow continuous flow during cleaning

-

Durable construction for industrial duty

-

Low pressure drop and long service life

-

Suitable for water, oils, fuels, chemicals, viscous fluids

Applications

-

Pump and valve protection

-

Cooling water and process water systems

-

Marine and offshore pipelines

-

Chemical and petrochemical plants

-

Fuel, lubricant, and oil transfer systems

-

Pulp & paper, power plants, and food processing

Certifications

-

ISO 9001 – Quality Management

-

CE Marking – European Conformity

-

PED – Pressure Equipment Directive (on request)

📩 Contact Us

For custom sizing, material selection, or OEM requirements, reach out to:

sales@smpssystems.com

Reviews

There are no reviews yet.