Description

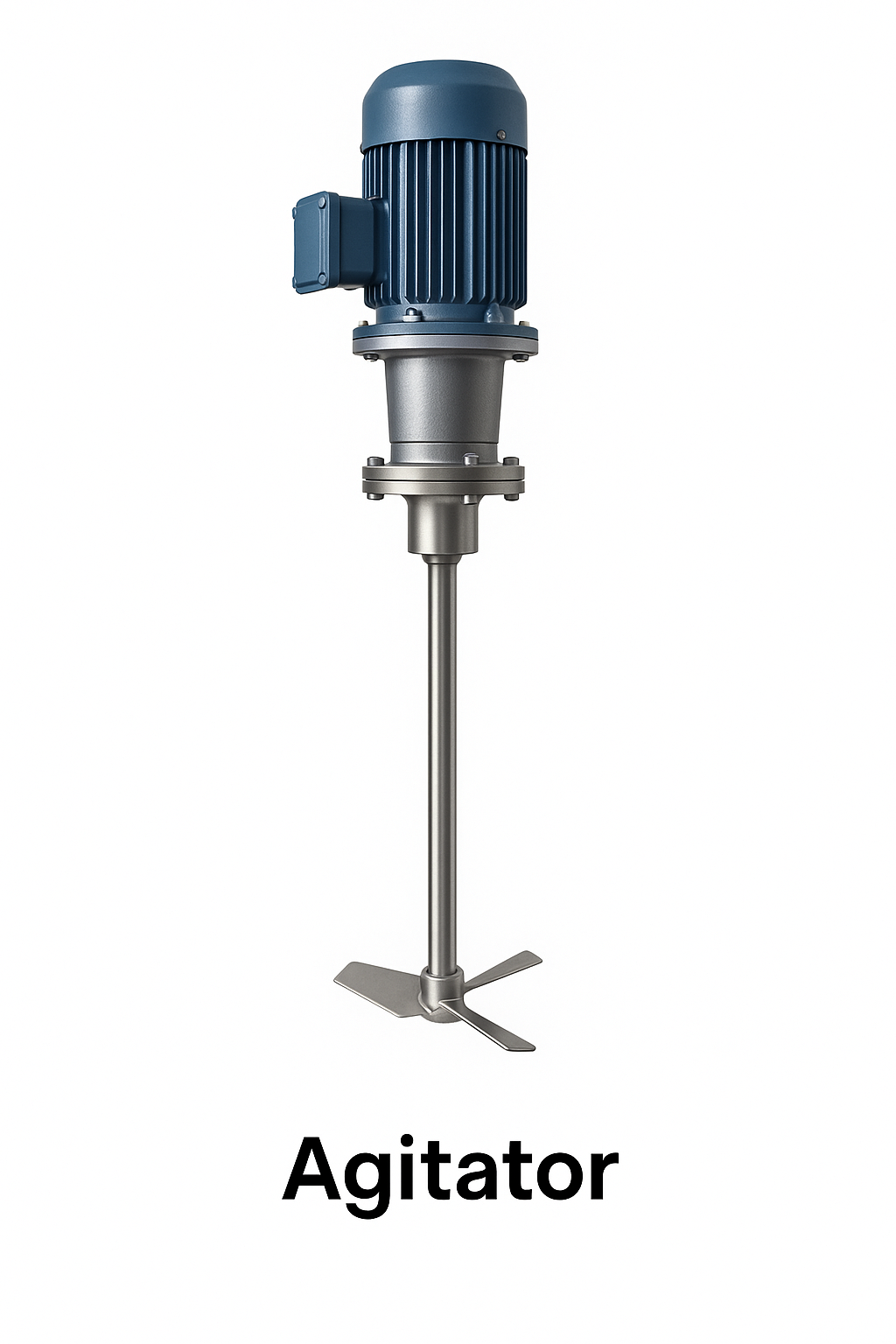

Our Industrial Mixers & Agitators are engineered to deliver consistent and efficient mixing solutions for a wide range of industrial applications. Designed for performance, flexibility, and durability, they are used in liquid blending, solids suspension, emulsification, and heat transfer across sectors like chemical processing, food & beverage, pharmaceuticals, cosmetics, and water treatment.

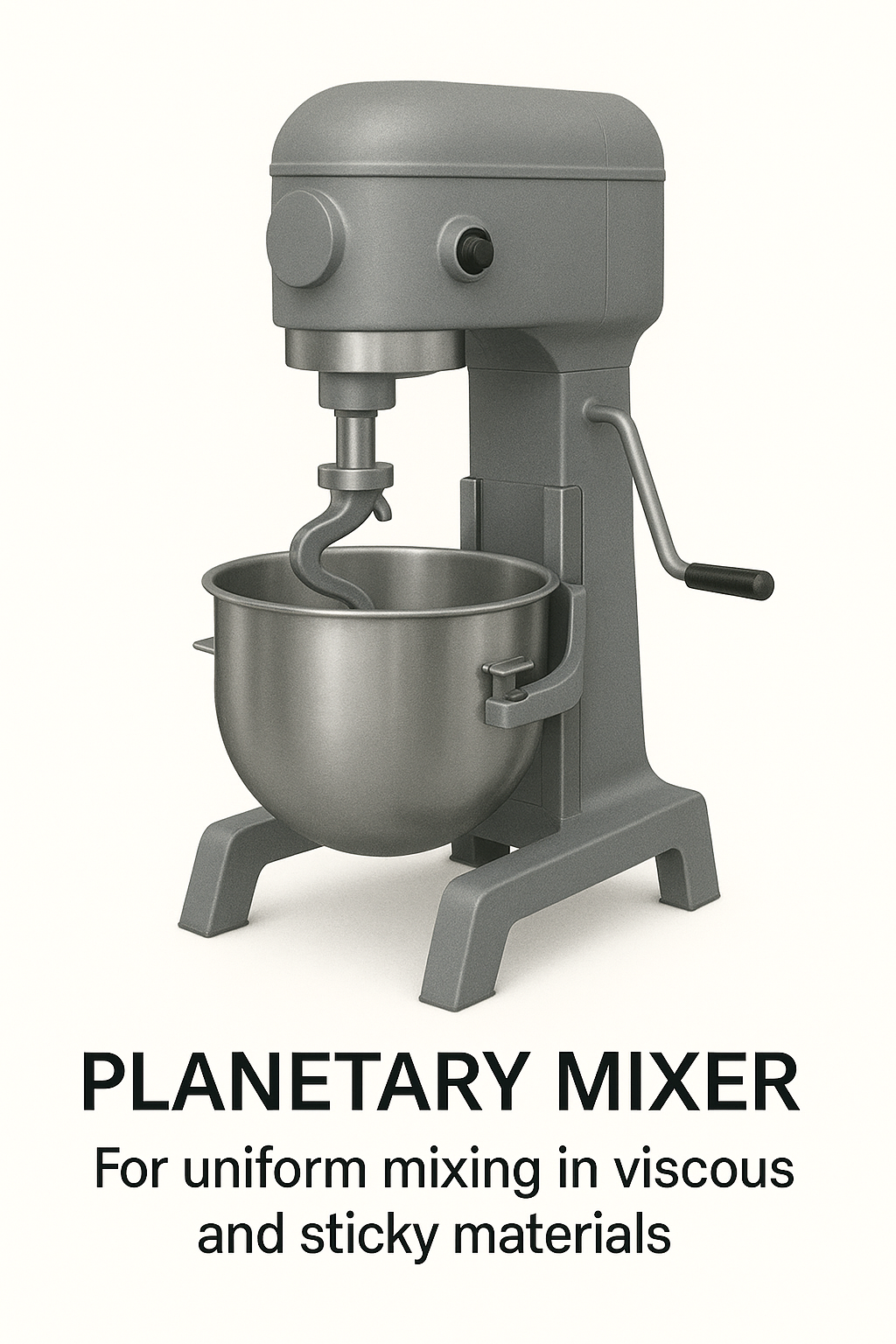

Available in top-entry, Ribbon mixer, Planetary Mixer, side-entry, and bottom-entry configurations, these systems are optimized for energy efficiency, process adaptability, and ease of maintenance. With precision control options and rugged construction, they ensure high mixing performance with long service life.

Certified to ISO 9001, CE, and applicable US/Canadian safety standards, our mixers and agitators guarantee compliance, process efficiency, and reliable operation.

Technical Specifications

| Parameter | Specification |

|---|---|

| Mixer Types | Top-Entry Mixers, Side-Entry Mixers, Bottom-Entry Mixers, Portable Agitators

Ribbon mixer, Planetary Mixer, |

| Impeller Types | Hydrofoil, Propeller, Turbine, Anchor, Paddle |

| Drive Types | Electric Motor, Pneumatic, Hydraulic |

| Power Range | From 0.18 kW to 250 kW (model dependent) |

| Speed Range | Fixed or Variable Speed (up to 3600 RPM) |

| Viscosity Handling | Up to 1,000,000 cP |

| Control System | VFD, PLC integration, torque monitoring, overload protection |

| Construction Materials | Carbon Steel, Stainless Steel (304/316L), Hastelloy, Duplex |

Features & Benefits

-

Efficient mixing performance for a wide range of viscosities

-

Modular designs to suit batch or continuous processes

-

Suitable for hygienic, corrosive, and high-temperature applications

-

Quick-release seals and easy maintenance access

-

Explosion-proof and ATEX-certified options available

-

Low energy consumption and optimized fluid dynamics

-

Custom impeller and tank-mounting configurations

Applications

-

Chemical mixing and reaction control

-

Food and beverage processing (sauces, syrups, dairy)

-

Pharmaceutical and cosmetic formulation

-

Water and wastewater treatment

-

Paints, coatings, and adhesives manufacturing

-

Slurry and suspension agitation

Certifications

-

ISO 9001 – Quality Management

-

CE Marking – European Conformity

-

CSA / cUL – Canadian Safety Certification (if applicable)

-

UL / NRTL – US Safety Certification (if applicable)

-

ATEX – Explosive Atmosphere Compliance (where required)

-

GMP Compliance for sanitary designs (optional)

📩 Contact Us

For custom mixer design, process integration, or OEM solutions, reach out to:

sales@smpssystems.com

Reviews

There are no reviews yet.