Description

-

-

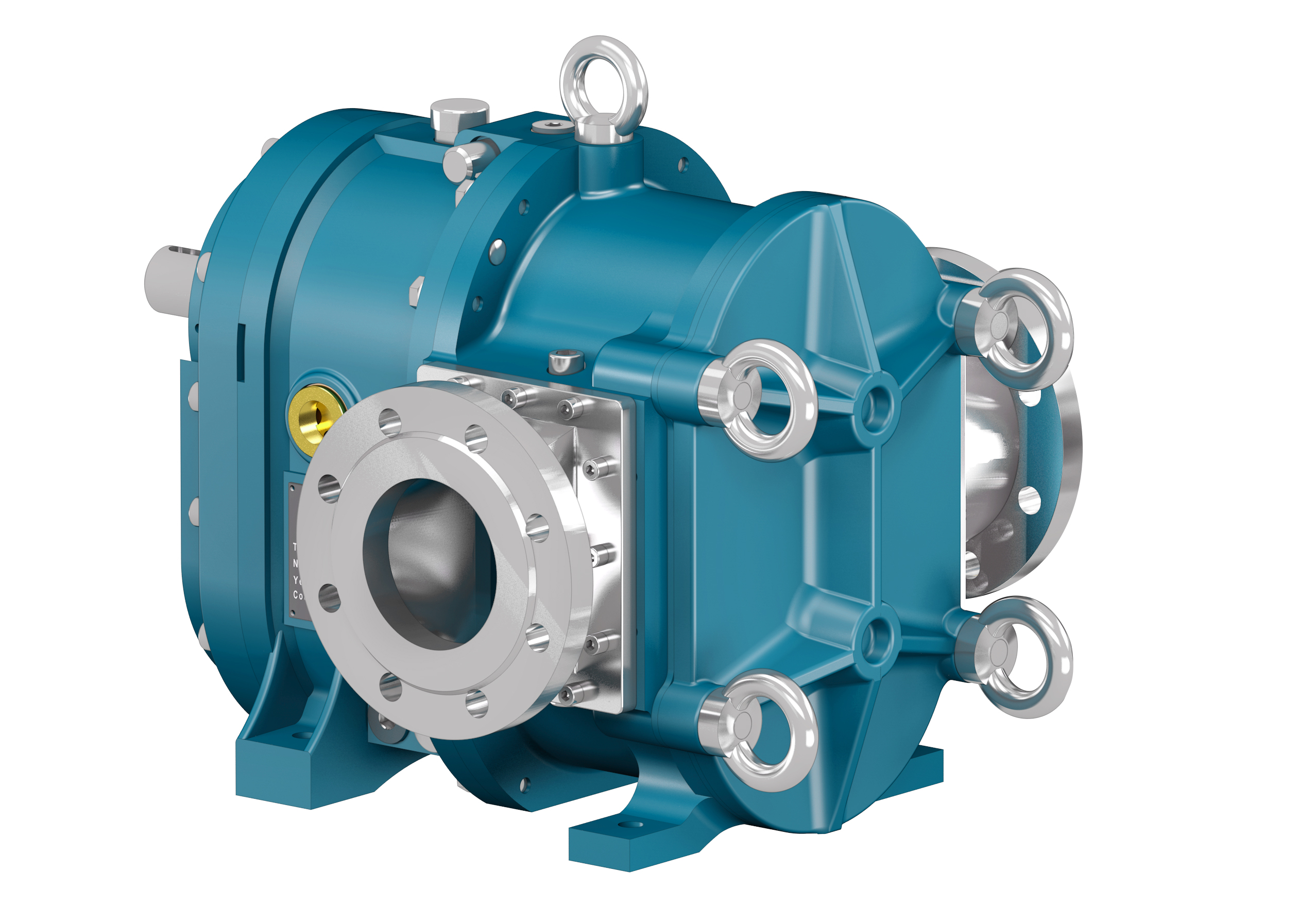

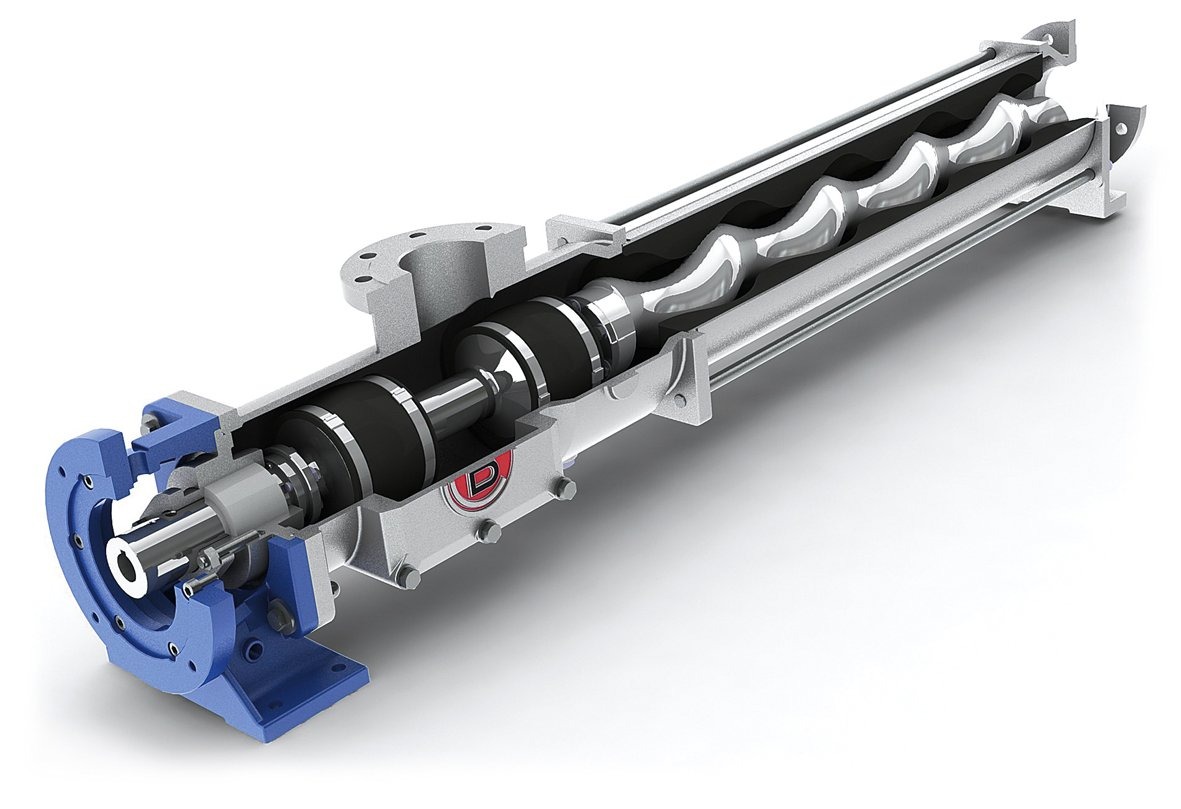

Our Positive Displacement Pumps (PD Pumps) deliver a constant flow rate regardless of pressure variations, making them ideal for transferring viscous, shear-sensitive, or abrasive fluids.

These pumps are engineered with precision components, durable materials, and advanced sealing systems to ensure smooth, leak-free, and energy-efficient operation.SMP SYSTEMS offers a full range of gear, screw, lobe, diaphragm, and peristaltic pumps, designed to meet CSA, CE, and ISO standards — ensuring reliability and compliance with Canadian industrial and environmental regulations.

Types of Pumps Offered:

-

Gear Pumps – For oils, fuels, and hydraulic fluids

-

Lobe Pumps – For food, dairy, and pharmaceutical products

-

Screw Pumps – For high-viscosity and multiphase fluids

-

Diaphragm Pumps – For chemical and corrosive liquid handling

-

Peristaltic (Hose) Pumps – For precise metering and low-shear transfer

-

Piston & Plunger Pumps – For high-pressure dosing and injection applications

Technical Specifications

Parameter Specification Pump Type Gear, Lobe, Screw, Diaphragm, Peristaltic, Piston Flow Range 0.1 – 3000 L/min (customizable) Pressure Range Up to 1000 bar (depending on type) Viscosity Range Up to 1,000,000 cP Temperature Range -20°C to +200°C Material of Construction Stainless Steel (SS304 / SS316), Cast Iron, Bronze, PTFE, EPDM Seal Type Mechanical, Gland, Magnetic Drive, Diaphragm Drive Options Electric, Hydraulic, Pneumatic, Belt Drive Mounting Type Base-Mounted, Close-Coupled, Portable Skid Protection Class IP55 / IP68 (depending on design)

Key Features:

-

Accurate and consistent flow rate under variable pressure

-

Handles viscous, abrasive, and shear-sensitive fluids

-

Energy-efficient with minimal pulsation and noise

-

Corrosion-resistant and compatible with diverse media

-

Self-priming and capable of dry running (depending on type)

-

Easy maintenance and part replacement

-

Available in sanitary, explosion-proof, and industrial configurations

Applications:

-

Food and beverage processing

-

Chemical and pharmaceutical dosing

-

Oil, lubricant, and fuel transfer

-

Paints, coatings, and adhesives

-

Water and wastewater treatment

-

Hydraulic and lubrication systems

-

Agriculture and fertilizer injection

Certifications & Compliance:

-

CSA Certified – Meets Canadian safety and electrical standards

-

ISO 9001 – Quality Management Systems

-

CE Marking – European conformity

-

3-A & FDA Compliance – For sanitary and food-grade applications

-

ATEX Certification – Explosion-proof variants available

-

RoHS – Environmental compliance

-

EHEDG – Hygienic design approval for food & pharma industries

📩 For product selection, pricing, or technical datasheets, contact us at: sales@smpssystems.com

-

-

Reviews

There are no reviews yet.